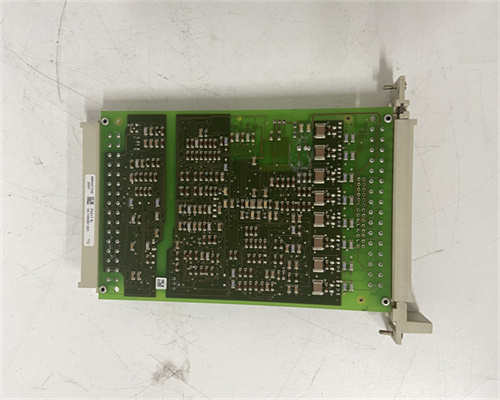

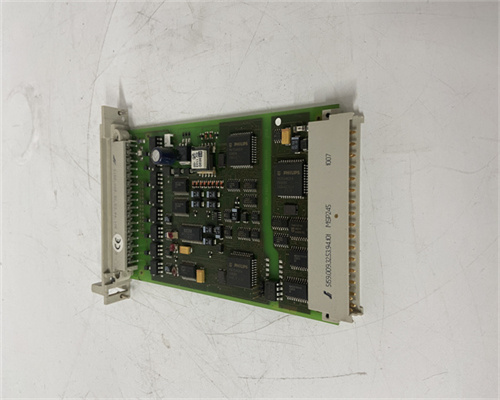

F6217

HIMA F6217 Production Description

Based on available information and the characteristics of similar HIMA products, here's a possible production process for the HIMA F6217:

Function:

The HIMA F6217 is likely an 8-channel analog input module used within safety instrumented systems (SIS) for industrial automation. It acts as an intermediary between:

- Field Sensors: The F6217 likely receives analog voltage or current signals from various sensors monitoring physical parameters like temperature, pressure, or vibration within a machine or process.

- Safety PLC (Programmable Logic Controller): The F6217 transmits the processed analog data to a safety PLC, which plays a central role in the SIS and makes safety-critical decisions based on sensor data.

Possible Production Process:

Component Sourcing: HIMA likely sources various electronic components for the F6217:

- High-precision analog-to-digital converter (ADC) to convert incoming analog sensor signals into digital data for processing by the microcontroller.

- Microcontroller or digital signal processor (DSP) to handle communication with sensors, perform signal conditioning and filtering, and potentially implement basic safety logic.

- Calibration circuitry to ensure accurate conversion of analog signals into digital values.

- Electrical isolation components (e.g., transformers, optocouplers) to isolate the module's internal circuitry from potentially noisy or high-voltage sensor signals, enhancing safety and preventing ground loops.

- Power supply circuitry to regulate power for different components of the module.

- Communication interface circuitry (e.g., fieldbus interface) to enable communication with the safety PLC.

- Housing components designed for mechanical protection and heat dissipation within a control panel.

Printed Circuit Board (PCB) Manufacturing: The design is likely created using computer-aided design (CAD) software. The PCB itself is fabricated according to the design, potentially involving multiple layers with etched circuitry and drilled holes for precise component placement.

PCB Assembly: Automated pick-and-place machines populate the PCBs with the procured electronic components. These components are then securely soldered onto the PCBs using reflow ovens or wave soldering techniques.

Calibration and Testing: The assembled unit undergoes rigorous testing and calibration to ensure proper functionality and safety:

- Functionality testing to verify accurate conversion of analog signals across the entire input range.

- Calibration using high-precision reference voltage or current sources to ensure accurate data acquisition from sensors.

- Communication protocol testing to confirm accurate data exchange with the safety PLC.

- Environmental testing to ensure the unit can operate reliably within specified temperature and humidity ranges.

- Compliance testing to confirm adherence to relevant safety standards for functional safety (e.g., IEC 61508).

Packaging and Shipping: Once all tests are passed, the HIMA F6217 is labeled according to regulations and securely packaged for shipment to distributors or end users.

Materials and Manufacturing Technology:

- High-quality electronic components with extended lifespans suitable for demanding industrial environments.

- Lead-free soldering processes complying with environmental regulations (if applicable).

- High-precision calibration equipment to ensure accurate analog-to-digital conversion.

- Automated testing equipment for consistent quality control and safety assurance.

- Stringent manufacturing procedures to meet high safety integrity level (SIL) requirements for safety-critical applications.

Finding More Specific Information:

Obtaining extremely detailed information about the specific production process for the HIMA F6217 might be challenging due to proprietary manufacturing practices and the sensitive nature of safety-critical components. Here are some suggestions for further exploration:

HIMA Resources:

- Search the HIMA website for product manuals or data sheets related to the F6217 analog input module. These resources might provide details about its features, specifications, supported sensor types, and certifications for functional safety compliance.

- HIMA might offer application notes or technical documents that discuss safety instrumented systems, analog signal processing in safety applications, and integration of analog input modules within SIS architectures.

Contact HIMA Directly: Reach out to HIMA's customer support or relevant department. They might be able to share general information about the F6217's functionalities but may not disclose confidential details about the production process due to its safety-critical nature.