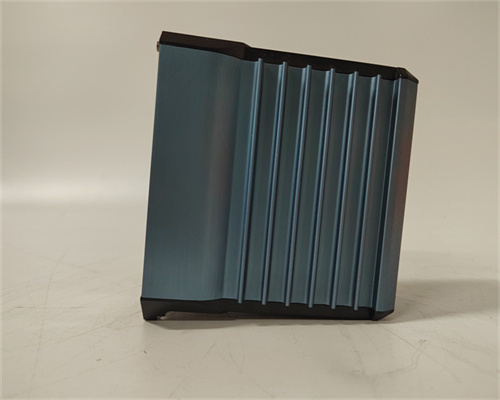

FOXBORO FEM100 P09

FOXBORO FEM100 P09 Production Description

Similar to the FOXBORO FBM227 P09, specific details about the production process for the FEM100 P09 are not publicly available. However, based on Foxboro's reputation and common practices in industrial process control, here's a possible breakdown of its production:

Components:

- High-quality electronic components:

- Analog or digital signal processing components depending on whether it processes analog sensor signals or digital inputs. This could involve:

- Power supply circuitry to regulate and distribute power throughout the module.

- Communication interface components (e.g., RS485) for data transmission to control systems (if applicable).

- Output components like relays or solid-state relays for controlling external devices (possible depending on functionality).

- Analog-to-digital converters (ADCs) if processing analog signals.

- Microcontrollers or digital signal processors (DSPs) for digital signal processing and control logic.

- The exact components depend on the FEM100 P09's functionality. It might include:

- Galvanic isolation components are likely used to isolate input, output, and power signals for safety and signal integrity (critical in process control).

- Housing suitable for industrial environments (e.g., flame-retardant plastic with proper heat dissipation features).

Production Stages:

Component Sourcing:

- Foxboro sources high-quality electronic components from reliable suppliers meeting their performance and reliability standards.

PCB (Printed Circuit Board) Manufacturing:

- The FEM100 P09 likely utilizes a PCB for its core functionalities. This PCB is likely fabricated according to Foxboro's design by a specialized PCB manufacturer.

PCB Assembly:

- Automated pick-and-place machines for accurate component placement.

- Reflow ovens or wave soldering techniques for secure connections.

- Additional hand soldering or rework for critical components (possible depending on the design).

- Automated and visual inspection to verify component placement and functionality.

- In a controlled environment with stringent quality control procedures, the electronic components are precisely placed and soldered onto the PCB. This might involve:

Calibration and Testing:

- Electrical testing to verify signal processing capabilities, input/output characteristics, and isolation effectiveness.

- Performance testing to assess response time, accuracy under various operating conditions (e.g., temperature, load).

- Functional testing to verify communication protocols and interaction with control systems (if applicable).

- Safety testing to ensure the device meets relevant safety standards (e.g., UL, CE) for potential hazards like overcurrent, short circuits, and ground faults.

- The assembled PCB undergoes calibration to ensure accurate signal processing and output according to its specifications (if applicable to the FEM100 P09's function).

- Rigorous testing is performed to ensure proper functionality, including:

Final Assembly and Packaging:

- The completed PCB is placed in its designated housing.

- Any additional components like terminal blocks for user connections or output modules (relays) are installed.

- The final assembly undergoes a final round of inspection for functionality, safety compliance, and cosmetic defects.

- Secure packaging is used to protect the module during transportation and storage.

Documentation:

- User manuals with clear instructions for safe installation, configuration, calibration (if applicable), and operation.

- Technical specifications detailing input/output signal ranges, accuracy, communication protocols (if applicable), environmental limitations, and calibration procedures (if applicable).

- Foxboro likely provides comprehensive documentation for the FEM100 P09, including:

Additional Notes:

- The specific production process might vary depending on the exact functionality and variant of the FEM100 P09 model.

- Foxboro likely has a robust quality management system in place to ensure the reliability and performance of their industrial process control products.